The working principle of the coal-fired boiler is that after the gas-powder mixture comes out of the coal mill, it is directly sent to the burner through the coal powder pipe, and is injected into the furnace for combustion. Pulverized coal burning in the furnace releases a lot of heat, and the center temperature of the flame is large.

The inside of the furnace is covered with a water-cooled wall composed of metal pipes. The heat released by combustion is mainly absorbed in the form of heat radiation by the heated surface of the water-cooled wall. However, due to the limitation of the heat load and the volume of the furnace, the flue gas temperature at the outlet of the furnace is generally still high.

In order to utilize this high-temperature flue gas, the superheater (divided into several levels), reheater, economizer and air preheater are also installed in the flue in turn. High-temperature flue gas flows through these heated surfaces in turn, and releases heat to these heated surfaces by means of heat transfer such as convection and radiation. The exhaust temperature from the air preheater is generally around. At this time, the flue gas can no longer be reused, and it is sent to a dust collector for separation, and most of the fly ash carried by the flue gas is removed, and then introduced into the chimney by the induced draft fan, and finally discharged into the atmosphere.

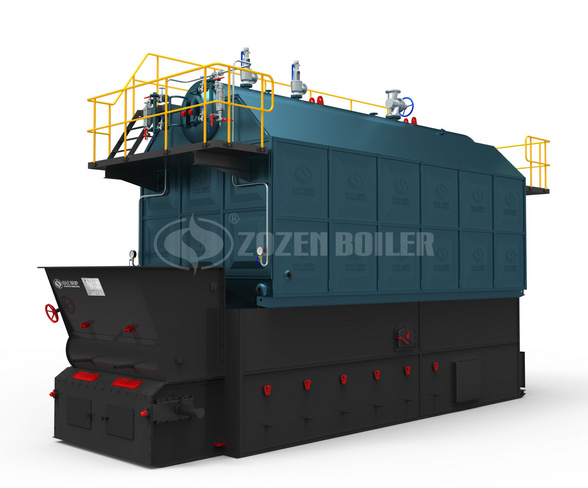

The coal-fired boilers produced by Zhongzheng can be divided into six series: SZL series double barrel vertical chain grate boiler, DZL series single barrel vertical chain grate boiler, SHX series circulating fluidized bed boiler, DHX series circulating fluidization Bed boilers, DHL series angle tube chain grate boilers and SHL series double drum bulk chain grate boilers.

Related Coal Fired Boiler

Zhongzheng Coal-fired Boiler has a wide range of fuels and can be applied to various coal types such as bituminous coal, anthracite coal, lean coal, and lignite. At the same time, special grate pieces are selected to ensure the smooth operation of the grate; scientific sealing structure; reasonable air adjustment device to achieve precise air distribution and improve combustion efficiency; can effectively control NOx emissions.

LEAVE A MESSAGE

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

Thanks for your subsmission! ZOZEN sales managers will contact you within 48 hours. Please check your email or whatsapp in time. If you do not receive the email in your normal inbox, please check your spam mail folder.